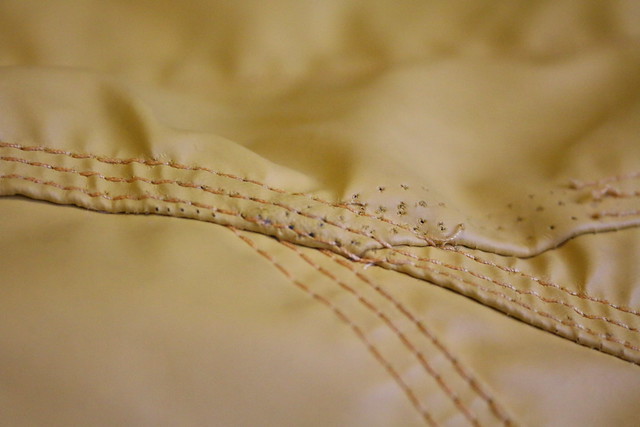

The coat pictured here is a RTW coat that Phil bought me as a birthday gift a couple of years ago. Once I started wearing it, I noticed a few instances of small ‘mistakes’ made during the coat’s construction. The coat is made from polyurethane (a fabric is laminated with polyurethane to make it waterproof), which – like leather – doesn’t recover when it is sewn or pinned, so every stitch leaves a permanent hole.

When I first received the coat I was mildly annoyed that my brand new coat, which I didn’t personally consider excessively ‘cheap’ (it cost £100), had sewing errors I would be annoyed if I made myself. However, it didn’t take me long to actually become quite fond of those errors, as they reminded me of the people (in China in this case) who constructed my coat, much more than any perfect stitching ever would have. It’s easy to forget that our RTW garments are sewn by people, not machines. It’s not so easy to forget when you can see evidence that they had to resort to the seam ripper – a feature of pretty much all of my own sewing projects.

The errors also reminded me of something else; that garment workers are typically expected to work at unrealistic speeds and for long hours, and that fast and cheap, is not compatible with care and attention to detail.